Specialized PVC Conveyor Belts

Amaron Rubber is a leading manufacturer and supplier of specialized custom PVC conveyor belts.

At Amaron Rubber, we specialize in crafting high-quality PVC conveyor belts that excel in durability, versatility, and cost-effectiveness. Our belts are resistant to abrasion and chemicals, meeting strict hygiene standards for industries like food processing. With flame-resistant options and flexible splicing methods, we provide reliable solutions tailored to diverse applications. Easy maintenance and a range of colors for efficient segregation make our PVC belts a practical and affordable choice for businesses prioritizing operational efficiency.

Green Antistatic PVC Conveyor Belt

Designed to combat static electricity buildup, this conveyor belt ensures the safe and efficient movement of materials. Its antistatic properties are crucial in industries where static charges can cause disruptions or hazards. This belt not only offers durability but also maintains a static-free environment, making it an essential choice for sectors like electronics, food, and pharmaceuticals.

Uses of Green Antistatic PVC Conveyor Belt:

Preventing static buildup in industries dealing with electronics, food, pharmaceuticals, and automotive.

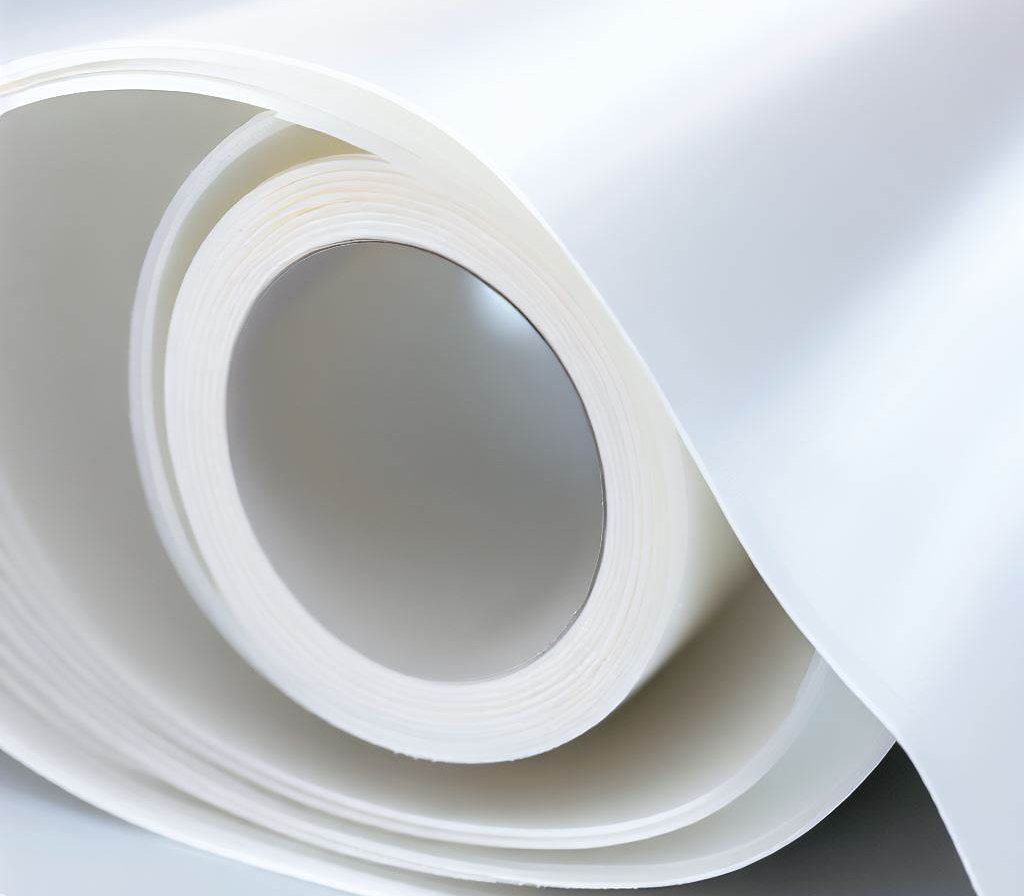

White Two Cloth Two Rubber Conveyor Belt

Known for its versatility, this conveyor belt consists of two fabric layers and two rubber layers. This composition provides both strength and flexibility, making it suitable for industries ranging from manufacturing to textiles. Its ability to handle diverse materials and withstand demanding conditions makes it a reliable choice for various production processes.

Uses of White Two Cloth Two Rubber Conveyor Belt:

Heavy-duty applications where strong grip and durability are needed.

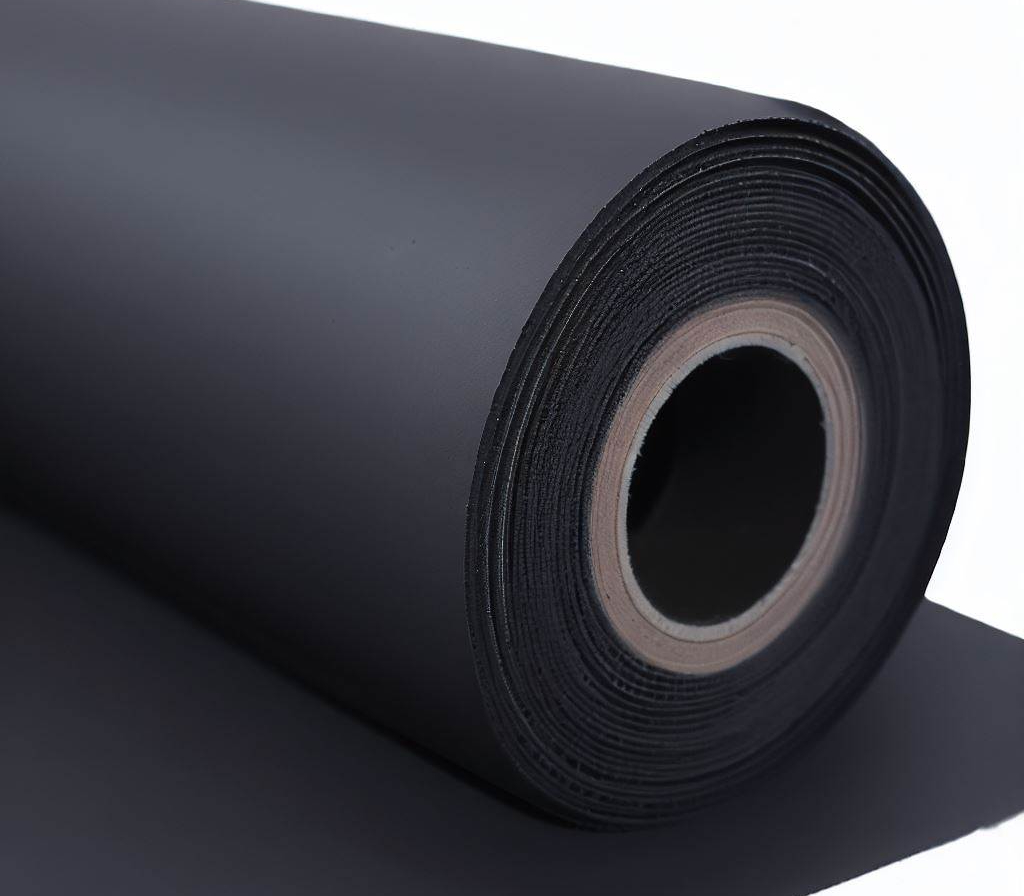

Black Matte Conveyor Belt

The black matte surface of this conveyor belt offers a unique advantage in applications where light reflection needs to be minimized. This makes it particularly useful in industries where visual inspections, such as quality control, are critical. The matte finish reduces glare, ensuring accurate assessments.

Uses of Black Matte Conveyor Belt:

Stages and entertainment setups to reduce glare and light reflection.

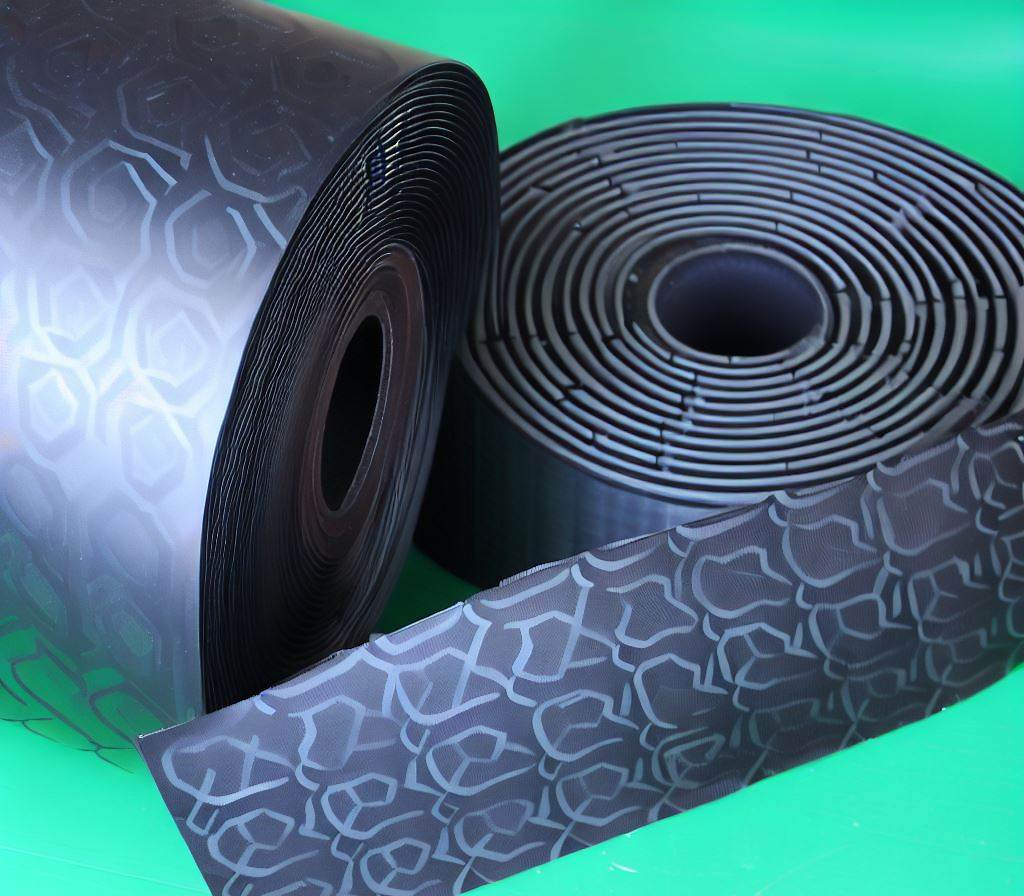

Golf Pattern Conveyor Belt

With its distinctive golf ball-like pattern on the surface, this conveyor belt offers enhanced grip and reduces slipping of materials. This feature is valuable in scenarios where items being conveyed might otherwise slide or shift. The golf pattern provides stability, making it useful in industries dealing with inclines or declines.

Uses of Golf Pattern Conveyor Belt:

Inclined conveyors and applications requiring secure material movement.

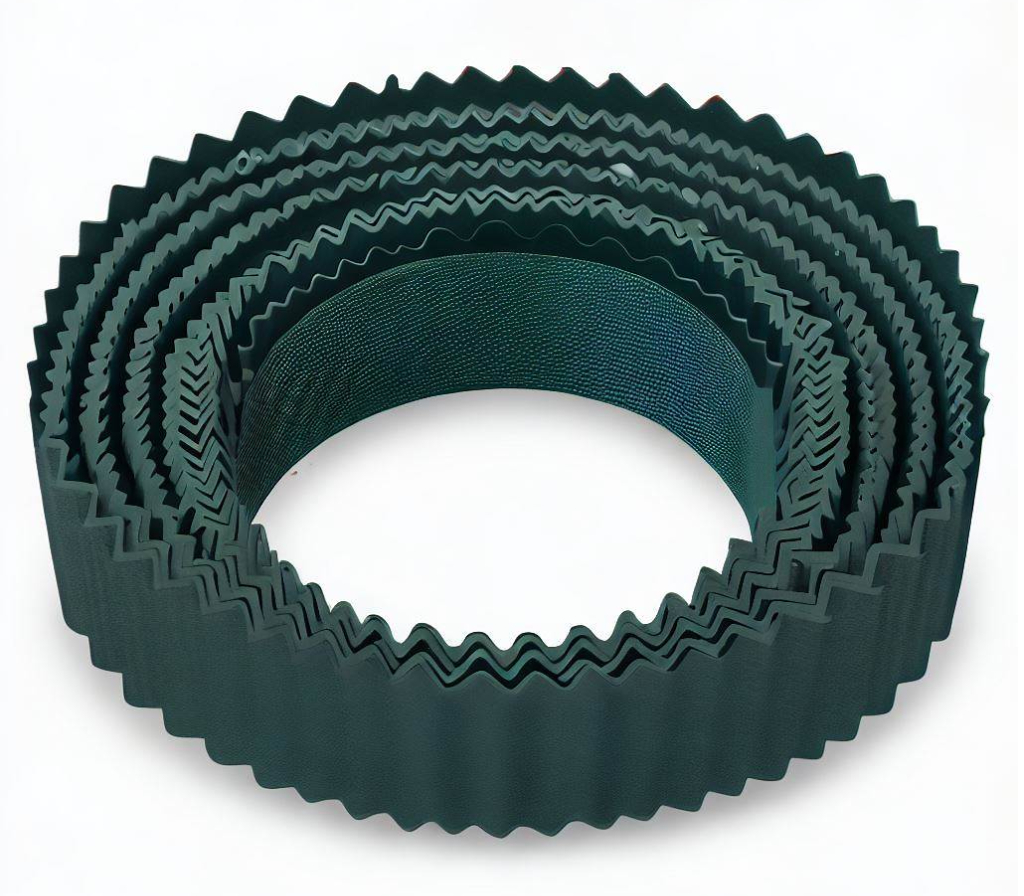

Antiskid Zigzag Conveyor Belt

Ideal for applications requiring maximum grip, the antiskid zigzag conveyor belt boasts a unique zigzag pattern on its surface. This design prevents materials from slipping, ensuring reliable movement even on steep inclines. This belt is commonly used in industries dealing with steep terrains or where secure material transport is crucial.

Uses of Antiskid Zigzag Conveyor Belt

Transporting materials on steep inclines to increase stability and prevent spillage.

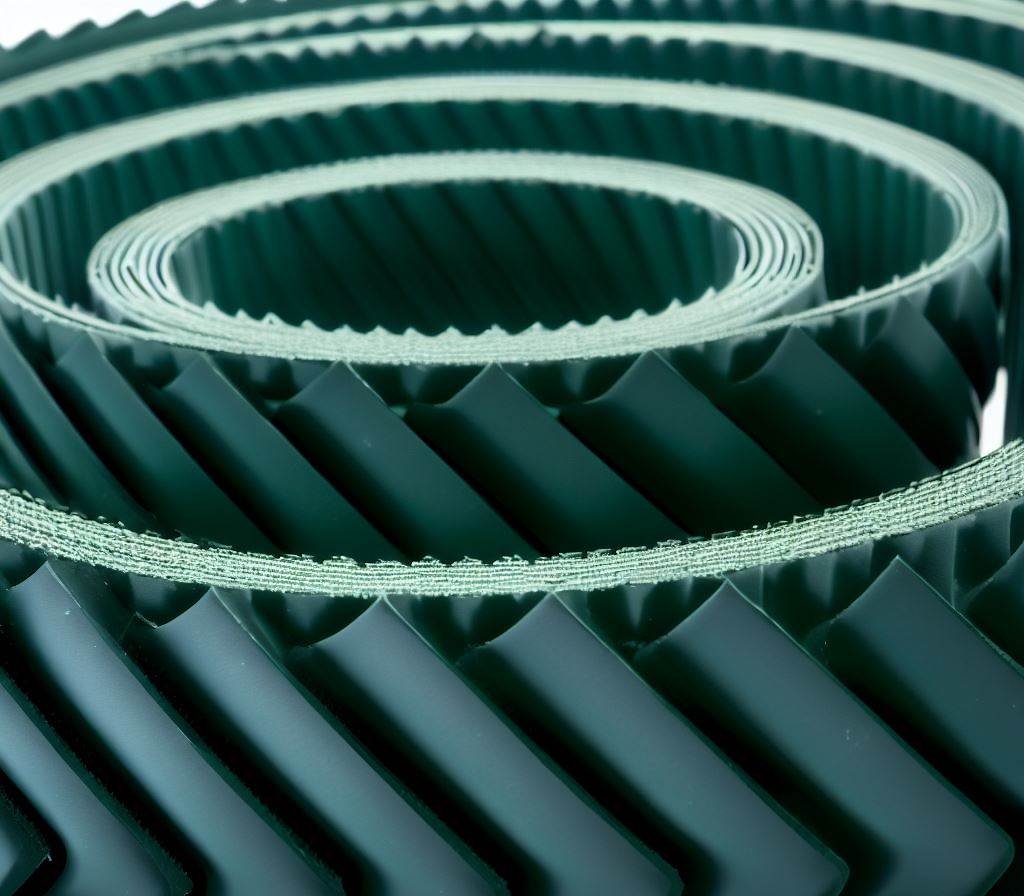

Green Bump Belt

The green bump belt is characterized by its textured surface with raised bumps. These bumps offer an increased level of grip, making it suitable for industries dealing with products that might otherwise slide or tumble during transport. Its ability to stabilize materials during movement ensures smoother processes.

Uses of Green Bump Belt:

Conveying goods on inclines and declines to prevent material slippage.

Grey Square Grid Sander Belt

With its square grid pattern, this conveyor belt is often employed in applications where materials need to be sanded or polished. The grid pattern provides a structured surface, facilitating even and consistent abrasive action, resulting in smooth finishes.

Uses of Grey Square Grid Sander Belt:

Woodworking and metalworking applications for efficient material removal and finishing.

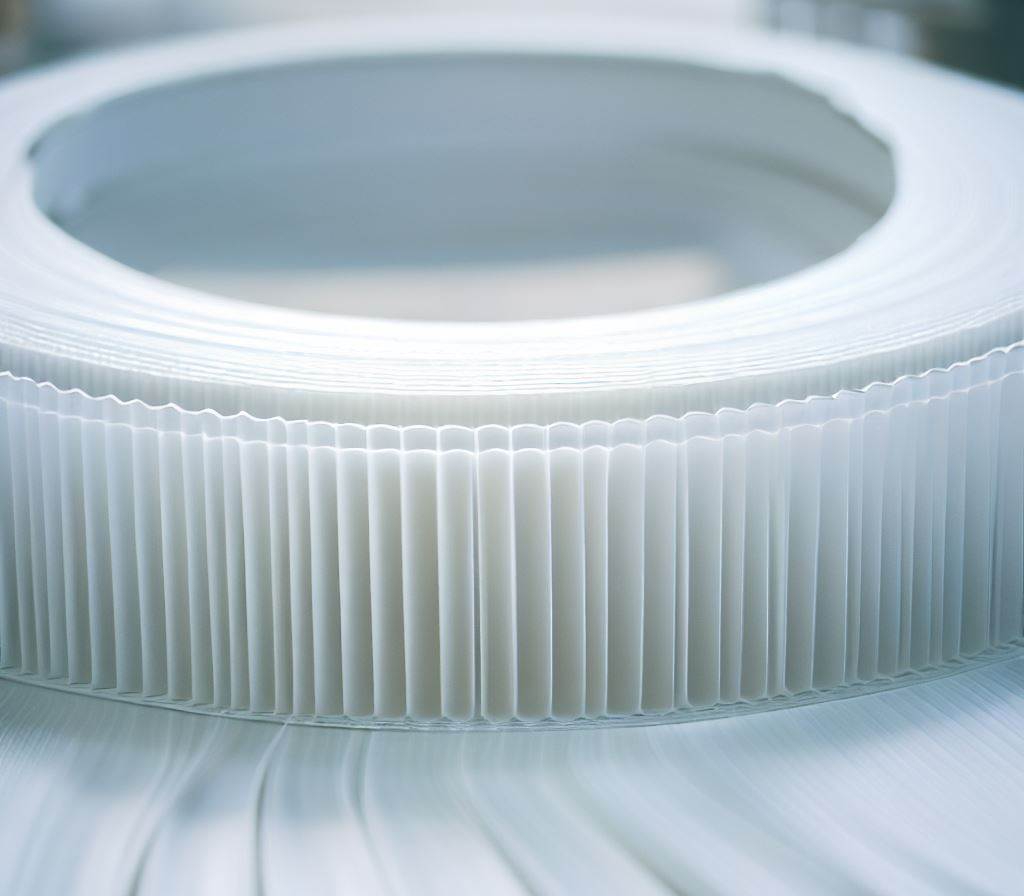

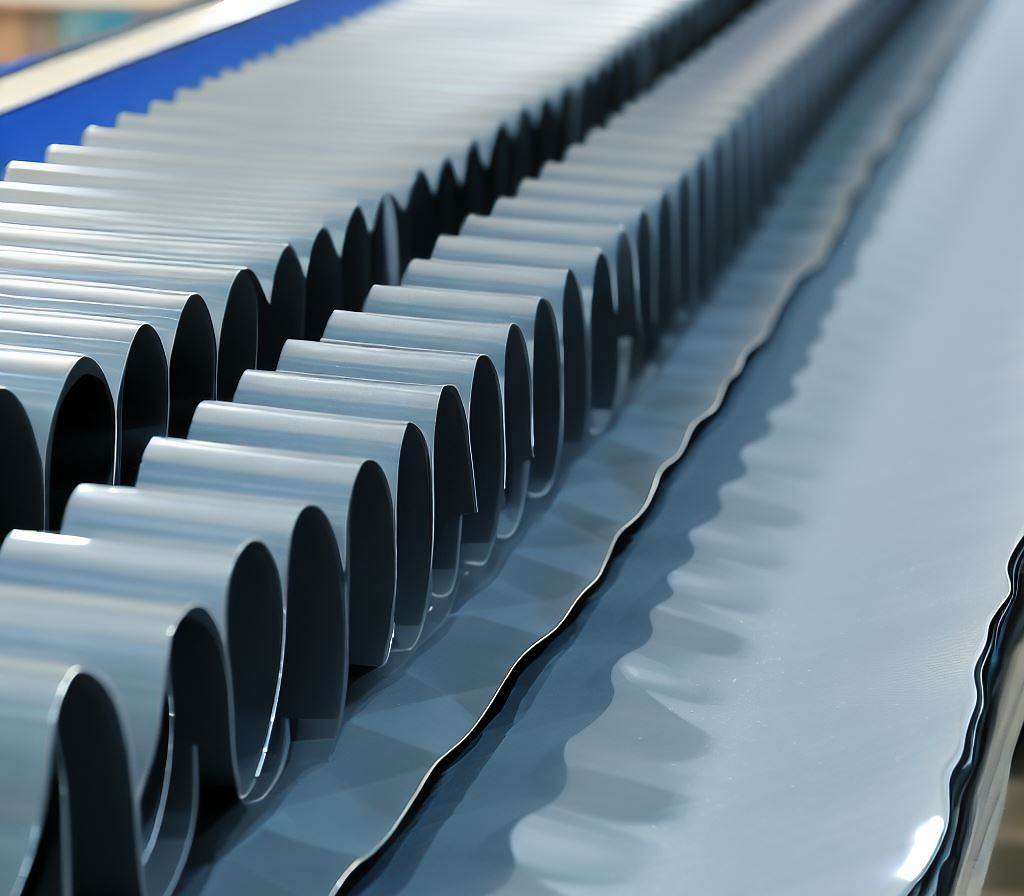

Skirt Edge Conveyor Belt

Featuring side skirts, this conveyor belt prevents materials from spilling over the edges during transport. This design is particularly useful when conveying fine or loose materials that tend to scatter. The skirt edge design helps contain the materials, reducing waste and maintaining a tidy workspace.

Uses of Skirt Edge Conveyor Belt:

Industries where material containment is crucial to prevent spillage and maintain cleanliness.

Specification of White Skirt Conveyor Belt

While the exact specifications of the White Skirt Conveyor Belt can vary, it typically features a white surface that prevents contamination and enhances visibility. The inclusion of a skirt edge further ensures materials remain within the belt’s confines, preventing spillage. This type of conveyor belt is often chosen for industries requiring hygiene, cleanliness, and containment.

Uses of White Skirt Conveyor Belt:

Industries prioritizing hygiene and containment while preventing material spillage.