Sponge Rubber Molding

Amaron Rubber is a leading manufacturer and supplier of high-quality sponge rubber molding.

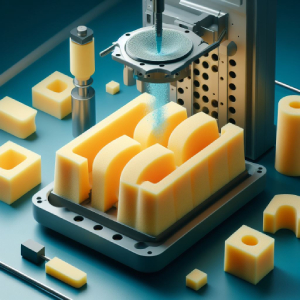

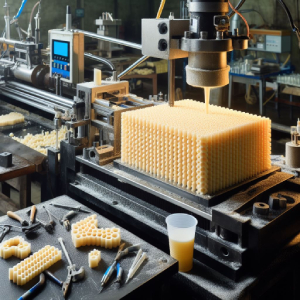

Sponge rubber molding creates flexible, shock-absorbing products with a porous structure. By mixing rubber with a blowing agent and molding it, we produce high-quality components like gaskets and seals. At Amaron Rubber, our custom sponge rubber molding ensures precision and durability for diverse applications, from aerospace gaskets to submersible seals. Trust us for unmatched performance and tailored solutions.

Key Features:

- Custom Engineering: Every product is meticulously engineered to your precise requirements, ensuring a perfect fit for your application.

- Material Expertise: Choose from a wide range of sponge rubber materials, including high-performance options like Viton, Silicone, EPDM, and more.

- Specialized Applications: We excel in creating components for aerospace, medical devices, military, and other demanding industries.

- Quality Control: Rigorous quality checks guarantee reliability and adherence to your specifications.

- Precision Molding: Our cutting-edge equipment allows for intricate designs and tight tolerances.

- Extreme Conditions: Our sponge rubber components withstand chemicals, UV exposure, and operate seamlessly in temperature extremes.

Applications:

- Aerospace: Seals, gaskets, and vibration dampening for spacecraft and aviation systems.

- Medical Devices: Custom sponge rubber components for medical equipment.

- Military: High-performance seals and insulation for military applications.

- Submersible Technology: Sealing solutions for underwater equipment.

- High-Temperature Environments: Components designed to withstand extreme heat.

- Electronics: Cushioning and insulation for sensitive electronics.

Technical Specifications:

- Material Options: Viton, Silicone, EPDM, Neoprene, and more.

- Customization: Tailored to your exact specifications.

- Size Range: From micro-components to large seals.

- Temperature Range: -70°C to 260°C (-94°F to 500°F).

- Density: Adjustable to meet your specific needs.

Why Choose Our Sponge Rubber Molding?

Our Sponge Rubber Molding process is your ultimate partner when it comes to reliability, precision, and performance. We are committed to delivering excellence and precision for your most demanding applications. Whether you need a single prototype or high-volume production, we have the expertise and resources to meet your unique requirements.

Experience the unparalleled precision, durability, and performance of our sponge rubber molding for your specific applications. Contact us today to discuss your project and receive a competitive quote. We’re ready to exceed your expectations with our expertise and tailored solutions.