Rubber Timing Belts

Amaron Rubber is a leading manufacturer and supplier of high-quality rubber timing belts.

Timing belts are essential components in a wide range of applications, including internal combustion engines, industrial machinery, and office equipment. They provide precise synchronization and efficient power transmission. Timing belts come in various types based on their materials and tooth designs, each offering distinct advantages for specific applications. Amaron Rubber is a leading supplier of timing belt to the US. We offer a wide range of products to meet the needs of our customers, and we are able to customize our products to meet specific requirements.

Structure of Timing Belts:

Timing belts are essential components in a wide range of applications, including internal combustion engines, industrial machinery, and office equipment, providing precise synchronization and efficient power transmission. They come in various types based on their materials and tooth designs, each offering distinct advantages for specific applications.

Main Materials and Categories:

Timing belts can be categorized based on their main materials into two primary groups:

Neoprene Fiber Rope Timing Belt:

- Materials: CR (Chloroprene Rubber) and NBR (Nitrile Butadiene Rubber) compounds

- Properties: CR and NBR are two types of synthetic rubber known for their durability and resistance to heat and oil. When used in neoprene fiber rope timing belts, they exhibit excellent dynamic flexibility, resistance to cracking, ozone, aging, heat, and wear.

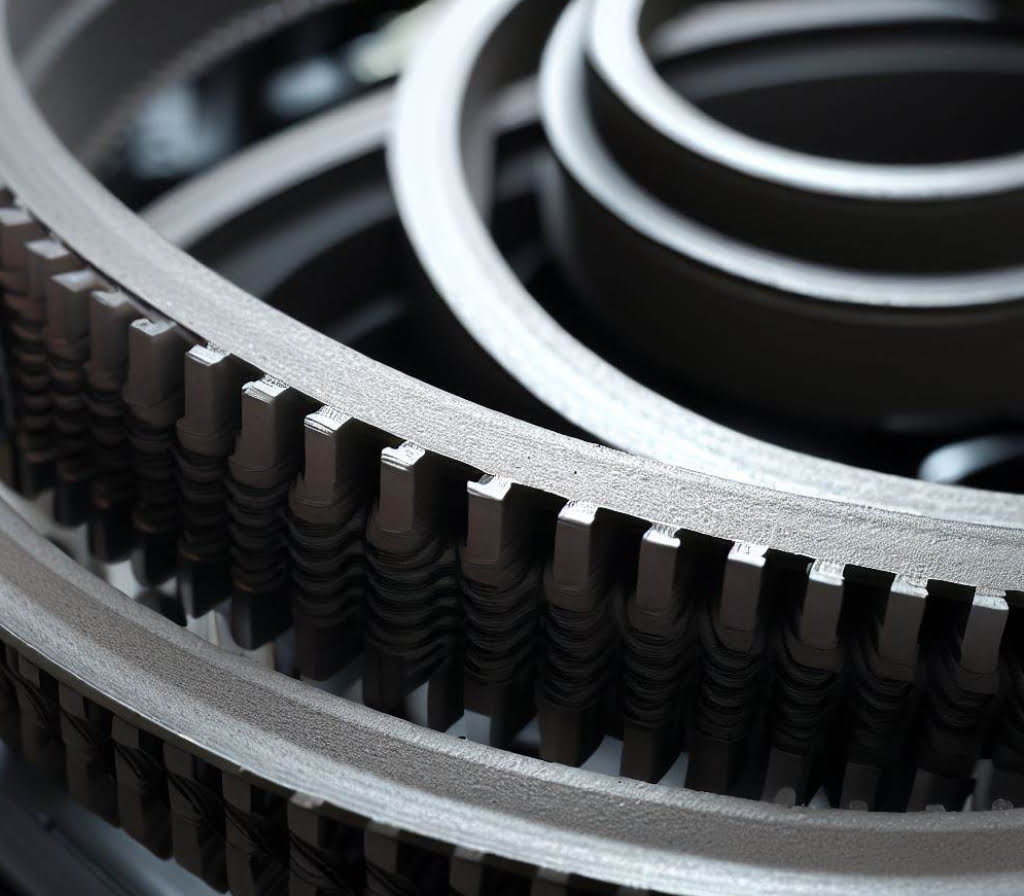

Polyurethane Plus Steel Wire Timing Belt:

- Materials: Imported thermoplastic polyurethane, a high-performance plastic known for its wear resistance and dimensional stability, with steel wire cores

- Properties: These belts offer high wear resistance and excellent movement during transmission. Their production process ensures minimal tolerance. They can also be coated with nylon for special applications and have an additional layer of polyurethane for corrosion prevention or handling high loads.

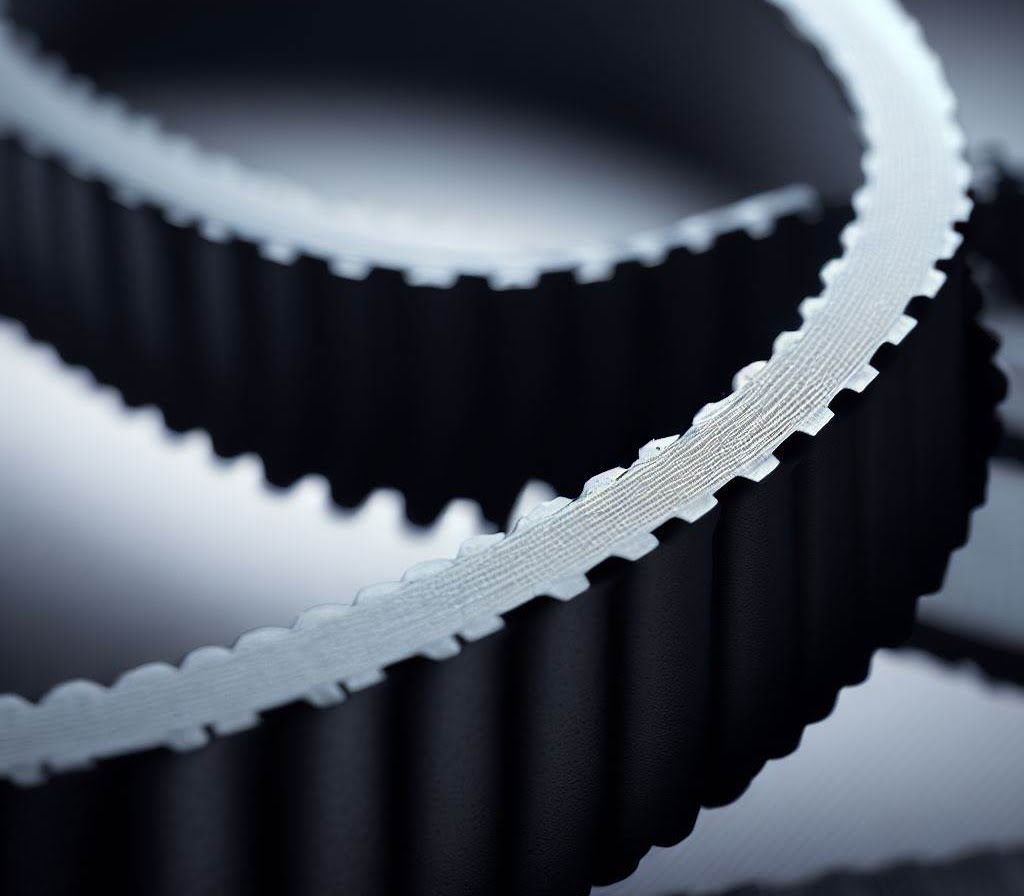

Double Sided Toothed Timing Belt Types:

Double Sided Toothed Timing Belts are designed for efficient and synchronized operation, offering precise timing, simultaneous movement, and improved efficiency. They come in two main types:

- Symmetrical Tooth Type (Code DA): This type is more common and is used in a wider range of applications where synchronization and precision are crucial.

- Staggered Tooth Type (Code DB): The staggered tooth type is used in applications where higher torque transmission is required, making it ideal for specific industrial needs.

Double Tooth Timing Belt:

These belts have an identical pitch and tooth design to single tooth timing belts, providing benefits like a lightweight structure and slip-free meshing transmission, which prevents the belt from slipping on the pulley. This results in more efficient and reliable power transmission. They find applications in industries such as large machinery, textiles, precision instruments, petrochemicals, communication cables, and other transmission systems.

Single Sided Toothed

Trapezoid Timing Belt 1.0

Trapezoid Timing Belts come in seven different materials, ranging from the lightest MXL to the super heavy Xxh, with XL, L, H, and XH in between. These belts are widely used in various industries, including printing, packaging, machine tools, textiles, and food processing, due to their varying weight capacities and applications.

Single Sided Toothed

Trapezoid Timing Belt 2.0

These belts are ideal for high-speed operations, space-saving, and exceptional stability, making them a perfect choice for precision drives in office machines and computers.

Single Sided Toothed Timing Belt

Arc Timing Belt 1.0 Half Arc:

This half arc Timing Belt offers improved performance and reliability, thanks to its accurate transmission ratio, high transmission efficiency (up to 98%), stable transmission, vibration absorption, and low noise. It finds applications in medical diagnosis equipment, sewing machines, air blowers, water pumps, spinning machines, and more.

Single Sided Toothed Timing Belt

Arc Timing Belt 2.0 Accurate Arc:

The Accurate Arc Timing Belt, mainly imported and manufactured by brand manufacturers, combines all the advantages of arc Timing Belts with higher transmission efficiency and lower noise. It is used in machinery and equipment for the textile, automobile, chemical fiber, cigarette, papermaking, printing, chemical industry, and is increasingly in demand in mining, metallurgy, steel machinery, and medical equipment.